Crisper Drawer Rail Repair

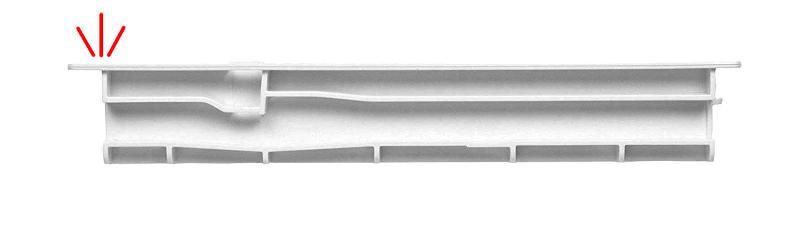

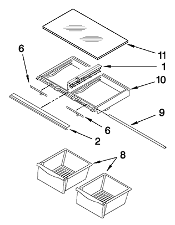

This repair solves a persistent failure in design of the Whirlpool EB9SHKXVQ05 bottom-freezer refrigerator, an otherwise fine appliance. Specifically, the refrigerator features two crisper drawers which are supported by a polystyrene rail extending through the center of the refrigeration compartment. (Parts 8 and 1 in the diagram below.) This rail hangs from two molded tabs, which have no support ribs or other reinforcement. When the drawers are stocked with heavy fruits and vegetables and handled in a hungry manner, a typical and forseeable design load, the front tab shears and the rail fails catastrophically. The rail part is known variously as P/N WPW10671238, W10671238, 67001057, and possibly other OEM numbers as well, since the same virtually identical refrigerator is also sold under brands other than Whirlpool. At the time of this writing, the part is available for $25-40 through eBay and Amazon.com. Reviews are terrible, since the replacement part is subject to the same failure mode.

I gambled on a replacement part, and it met the same fate after approximately

a year. Rather than throw good money after bad, I resolved to solve the

problem permanently.

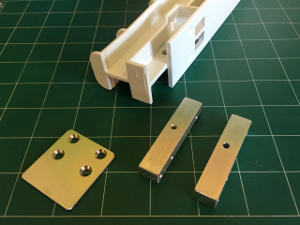

First I found a piece of stainless steel plate, and milled it to the 1-1/2"

width of the broken tab. I milled off the top layer of plastic from the rail,

making a recess for the steel plate while leaving enough plastic to support

a bracket. I found that some offcut 3/8x1/2" aluminum bar stock fit almost

perfectly inside the structural ribs, to anchor the plate. Finally I used a

1/4" OD standoff as a pin through the center rail, for additional load

distribution. The lower cross-section of the rail was 1.23" wide; I got lucky

and found a .483" (31/64"?) standoff which exactly spanned the distance between

the two aluminum bars. I drilled, tapped and countersunk all components for

#6-32 stainless steel flat head screws.

I gambled on a replacement part, and it met the same fate after approximately

a year. Rather than throw good money after bad, I resolved to solve the

problem permanently.

First I found a piece of stainless steel plate, and milled it to the 1-1/2"

width of the broken tab. I milled off the top layer of plastic from the rail,

making a recess for the steel plate while leaving enough plastic to support

a bracket. I found that some offcut 3/8x1/2" aluminum bar stock fit almost

perfectly inside the structural ribs, to anchor the plate. Finally I used a

1/4" OD standoff as a pin through the center rail, for additional load

distribution. The lower cross-section of the rail was 1.23" wide; I got lucky

and found a .483" (31/64"?) standoff which exactly spanned the distance between

the two aluminum bars. I drilled, tapped and countersunk all components for

#6-32 stainless steel flat head screws.

The rail was reinstalled and performs exactly as designed, for purposes of the

owner if not the replacement parts market.

Some might eagerly tout 3D printed thermoplastic for this type of application.

I myself prefer metal.

Contact: reboots at g-cipher.net

The rail was reinstalled and performs exactly as designed, for purposes of the

owner if not the replacement parts market.

Some might eagerly tout 3D printed thermoplastic for this type of application.

I myself prefer metal.

Contact: reboots at g-cipher.netXHTML and CSS compliant

:wq